Izingxenye ze-Nabtesco Hydraulic Parts, Hydraulic motors Parts, Piston motors Parts

I-Hydraulic Pump Accessories Incazelo

Iphampu ye-hydraulic iyingxenye ebalulekile yanoma yiluphi uhlelo lwe-hydraulic, esebenza njengomthombo wayo oyinhloko wamandla. Iguqula amandla emishini abe amandla asebenza ngamanzi, abalulekile ekusebenzeni kwemishini ehlukahlukene kanye nezinqubo zezimboni. Izesekeli zephampu, eziklanyelwe ukuthuthukisa ukusebenza kwayo nokuthembeka, zibaluleke ngendlela efanayo.

Izinsiza ezifana nezihlungi, amageji, namavalvu zidlala indima ebalulekile ekusebenzeni kahle kwephampu kanye nalo lonke uhlelo olusebenza ngamanzi. Izihlungi ziqinisekisa ukuthi uketshezi olusetshenziswa ohlelweni alunakho ukungcola, okungalimaza iphampu noma ezinye izingxenye. Ama-gauge ahlinzeka ngokuqapha kwesikhathi sangempela komfutho wamanzi namazinga okugeleza, okuvumela ukulawula okunembayo nokwenza kahle. Futhi ama-valve alawula ukugeleza koketshezi ohlelweni, alawula ukucindezela nokugeleza ngokuvumelana nezidingo zohlelo lokusebenza.

Ngaphezu kwalezi zinsiza ezibalulekile, ezinye izinto ezinjengamapayipi, okokufakwayo, nezigxivizo nazo zibalulekile ekusebenzeni kahle kwephampu nohlelo lwe-hydraulic. Amapayipi, asetshenziselwa ukuthwala uketshezi ukuya nokubuya epompo, kufanele abe namandla futhi aqine ukuze amelane nokucindezela nezinga lokushisa elidlulele okuhlangatshezwana nalo ohlelweni. Ukufakwa kuqinisekisa ukuthi amapayipi axhumeke ngokuphephile empompini nakwezinye izingxenye, kuyilapho ama-seal avimbela ukuvuza ezindaweni ezibalulekile.

Ukukhethwa kwezesekeli zephampu ye-hydraulic kufanele kusekelwe ezintweni ezifana nomthamo wephampu, izidingo ezithile zohlelo lokusebenza, kanye nezimo zokusebenza zesistimu. Isibonelo, amaphampu anengcindezi ephezulu adinga izihlungi zekhwalithi ephezulu kanye nama-seal ukuze amelane nengcindezi eyengeziwe. Ngaphezu kwalokho, izesekeli kufanele zihambisane nephampu noketshezi olusetshenziswayo, kanye nokuhlangabezana nanoma yimiphi imithetho yokuphepha noma izindinganiso zomkhakha.

Ukugcinwa njalo nokuhlolwa kwezesekeli zephampu ye-hydraulic kubalulekile ukuze kuqinisekiswe ukuphila kwazo isikhathi eside nokusebenza kwazo. Lokhu kuhlanganisa ukuhlola ukuvuza, ukushintsha izingxenye ezigugile, nokuhlanza noma ukushintsha izihlungi ngokuvumelana neshejuli. Ukunakekelwa okufanele kungasiza ekuvimbeleni ukwehla kwesikhathi esibizayo futhi kunwebe isikhathi sokuphila sepompo kanye nezinsiza zayo.

Sengiphetha, izesekeli zephampu ye-hydraulic ziyingxenye ebalulekile yanoma iyiphi isistimu ye-hydraulic, ethuthukisa ukusebenza kwepompo, ukwethembeka, nokuphepha. Kubalulekile ukukhetha izesekeli zekhwalithi ephezulu ezihambisana nepompo kanye noketshezi olusetshenziswayo, kuyilapho uqinisekisa ukugcinwa nokuhlolwa okuvamile ukuze kunwetshwe ukuphila kwesistimu.

Ilayisha izithombe... |

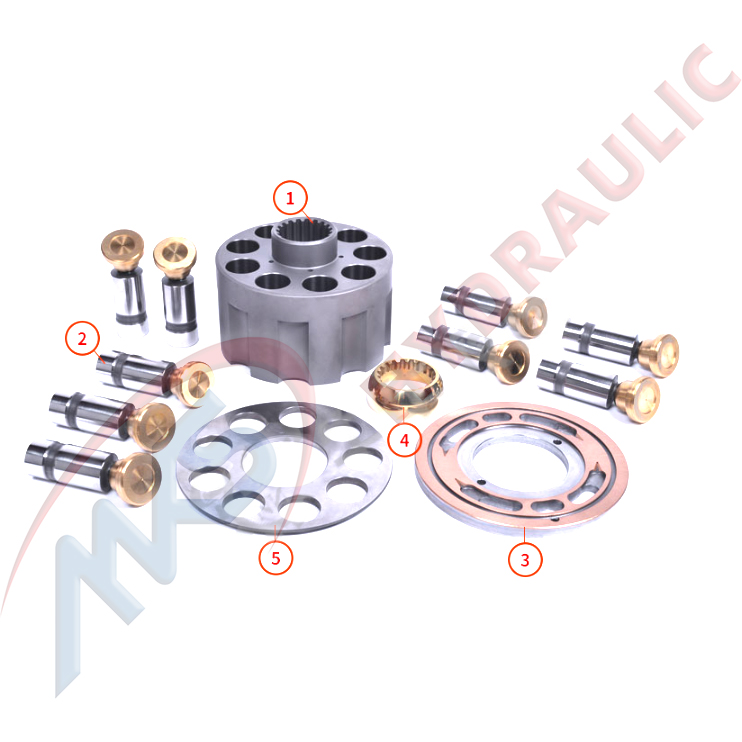

GM03/05/06/07/08/09/10/17/18/20/23 1. isilinda block 2. isicathulo se-piston 3. umhlahlandlela webhola 4. ipuleti le-valve 5. ipuleti lokugcina |

Ilayisha izithombe... |

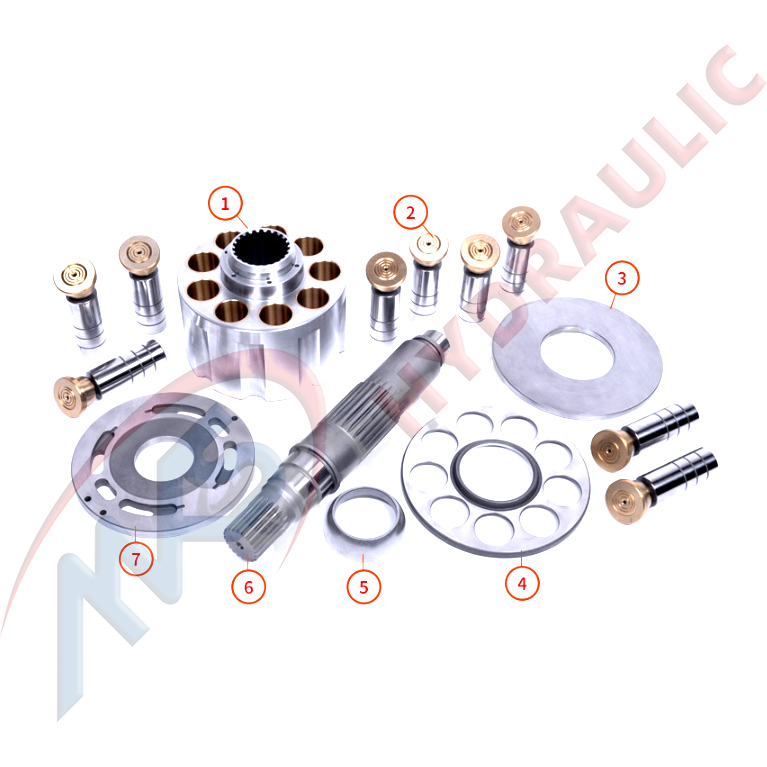

GM35VA 1. isilinda block 2. isicathulo se-piston 3. ipuleti le-thrust 4. ipuleti lokugcina 5. umhlahlandlela webhola 6. shaft yokushayela 7. ipuleti le-valve |

|

GM03/05/06/07/08/09/10/17/18/20/23/24/28/35/38VL 1. isilinda block 2. isicathulo se-piston 3. ipuleti le-valve 4. umhlahlandlela webhola 5. ipuleti lokugcina |