Amaphampu we-PVXS Hydraulic Open circuit, i-Rexroth Axial piston variable Iphampu yokucindezela okuphezulu

Isigaba Esijwayelekile se-Open Loop PVX Pump

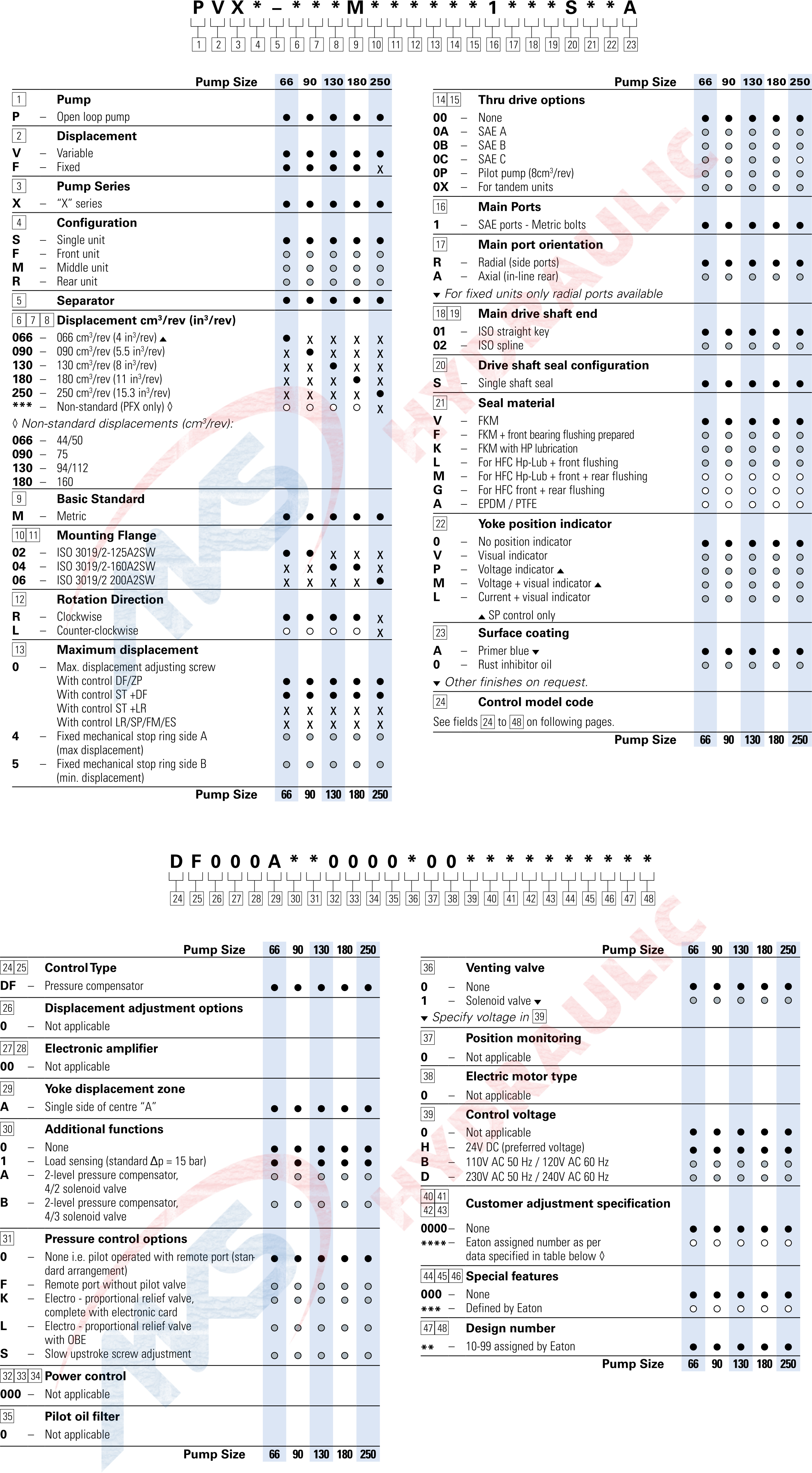

Izilawuli zokufuduka:

I-ES - Ukulawula ukususwa kwezimoto zikagesi

HG - Isilawuli sokususa isondo lesandla (Isici esikhethekile)

I-FE - Ukulawula ukulungisa isikulufu (Isici esikhethekile)

I-DF - Isinxephezelo sokucindezela siyalawulwa

I-DQ - Ukulawulwa kwe-Moring

I-LR - Ukulawula amandla ngomkhawulo wengcindezi

I-SP, SM - Ukususwa ngokulingana nesignali kagesi

I-DP - Ukususwa ngokulingana nesignali yengcindezi

Izidingo zokushaywa kwekesi

I-valve yokuhlola akumele isetshenziswe epayipini lokudonsa amanzi. Ipayipi lokudonsa amanzi kufanele lingene ngaphansi kwezinga likawoyela endaweni yokugcina amanzi.

Kuzo zonke ezinye izimo ezinomfutho ophansi <20 bar (<300 psi) nokugeleza okuphansi (<10% we-Qmax) ukuguquguquka kwekesi kuyadingeka.

Ngokusebenza ngoketshezi olukhethekile lwe-HFB ne-HFC, ukushaywa kwekesi kuyanconywa.

Flushing Flow

Ukugeleza kwepompo ngekesi lepompo kufanele kube>ku-1% wokugeleza okuphezulu kwepompo. Ukugeleza okuphezulu kokuguquguquka kuncike ekucindezelweni kwecala.

Isingeniso

• Amaphampu e-axial piston anomklamo we-swashplate wokusebenza okuthembekile nokuphila isikhathi eside.

• Cindezela kufika kubha engu-420. Isivinini esilinganiselwe kufika ku-1800 min-1. Isivinini esiphezulu singenzeka.

• Amashafu nama-bearings amakhulu.

• Izingxenye ezijikelezayo nezilayishwe ingcindezi zilinganiselwe.

• Iphampu yokushayela ehlanganisiwe, isihlungi namavalvu okusiza ukucindezela ayatholakala.

• Idizayini "yebhulokhi yokwakha" inikeza lawa maphampu uhlelo olubanzi lokusebenza.

• Izikhathi zokuphendula ezisheshayo.